Electric motors are one of the most dependable pieces of equipment in industries. The smooth operation of electric motors is important because they have a massive impact on a business’s productivity and profit. With advancements in technology, now electric motors are much more competent and dependable than their earlier counterparts. These motors are designed to withstand mistreatment, but they may fail to perform if they are not given proper maintenance. To avoid any trouble and prevent your electric motor from failing catastrophically, it is necessary to provide it with an ideal operating environment along with proper maintenance. Below, we will discuss the essential preventive maintenance tips to keep your electric motor in a good working condition.

1. Lubrication is essential

To increase the life of the bearing, proper lubrication is essential. Without proper lubrication, the bearings will wear out prematurely; however, make sure not to over-lubricate them. Bearing lubrication includes two items, that is, oil and grease. Both over greasing and under greasing are harmful to bearings. Moreover, it is important only to use the lubricant recommended by the manufacturer and check your manual or the manufacturer’s website to know the proper interval for lubrication.

2. Moisture Control

Electric motors are vulnerable to moisture. If the motor is left unused, its interior parts tend to build up moisture, leading to rust and other related problems. Therefore, to address this issue, use grease infused with a rust prevention substance to oil up bearing assemblies.

3. Visual inspections on the motor

Many potential problems can be avoided by just conducting a visual check on an electric motor. Regularly check it and find signs of corrosion or dirt buildup on its individual components. Also, observe the motor windings or burned odor from overheating and check the bearings if there is any vibration or noise.

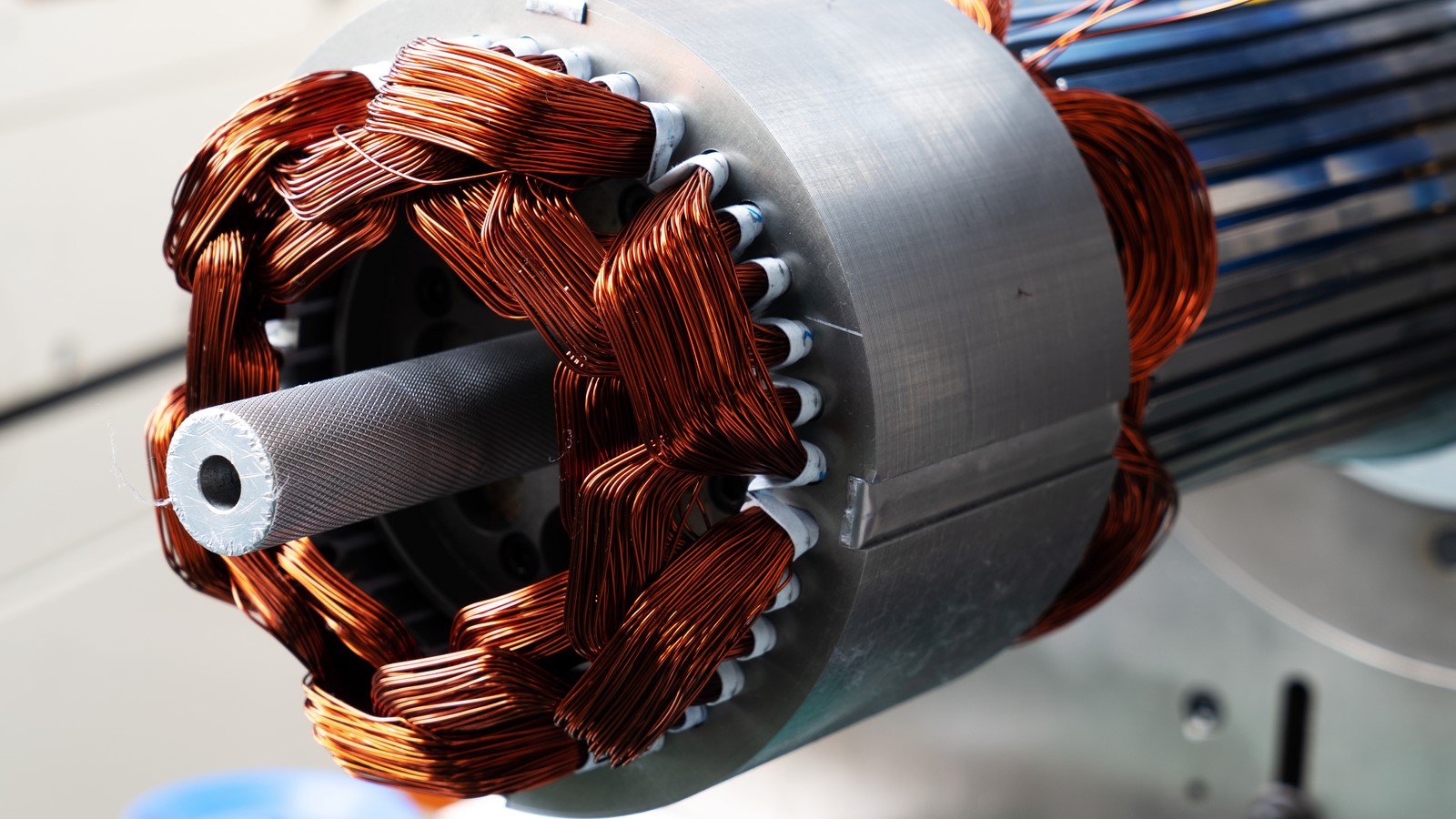

4. Rotor and Stator

The rotor and stator are the two most essential parts of your electric motor. The proper functioning of the motor depends on the efficiency of these components. Three factors are mostly responsible for the motor failure, and these losses are- Rotor loss, Stator loss, and Core (Iron) loss. To keep the rotor and stator in good condition, use a feeler gauge to check the gap between the stator and the rotor for equal clearance all the way around.

5. Excessive Vibrations are harmful

If a motor is exposed to excessive vibrations when it’s not working, the bearings tend to vibrate, and the friction between the bearing and other metal surfaces rises. This is obviously not favorable for your motor; therefore, make sure to protect the motors from continuous vibration caused by another running motor or tool nearby.

6. Repair and Maintenance Record

Prepare a repair and maintenance history record to avoid duplicate services in the future. This record will serve as a reference to past problems and issues with the motor. In case you notice a pattern, you can preemptively address a problem pattern. Therefore, this record will work as a guide as to what kind of predictive and preventative maintenance you need to take. Apart from proper maintenance, it is crucial to trust a reliable and experienced electric motor service only. To prolong the life of an electric motor, planned and periodic inspections are necessary to discover potential breakdowns. Be it household or industrial electric motors, regular maintenance and proper repairing ensure enhanced performance.